SULOTIONS

Choose Our Fixed Barcode Scanners: Elevate Efficiency, Ensure Accuracy

Applications and Use Cases:

Fixed-mount barcode scanners serve as the backbone of high-speed, high-volume scanning applications across industries such as manufacturing, warehousing, and logistics. They seamlessly integrate into conveyor belts, assembly lines, and automated processes, enabling hands-free, continuous barcode scanning. By eliminating the need for manual intervention, these scanners significantly enhance efficiency, reduce errors, and boost throughput.

Features and Functionality:

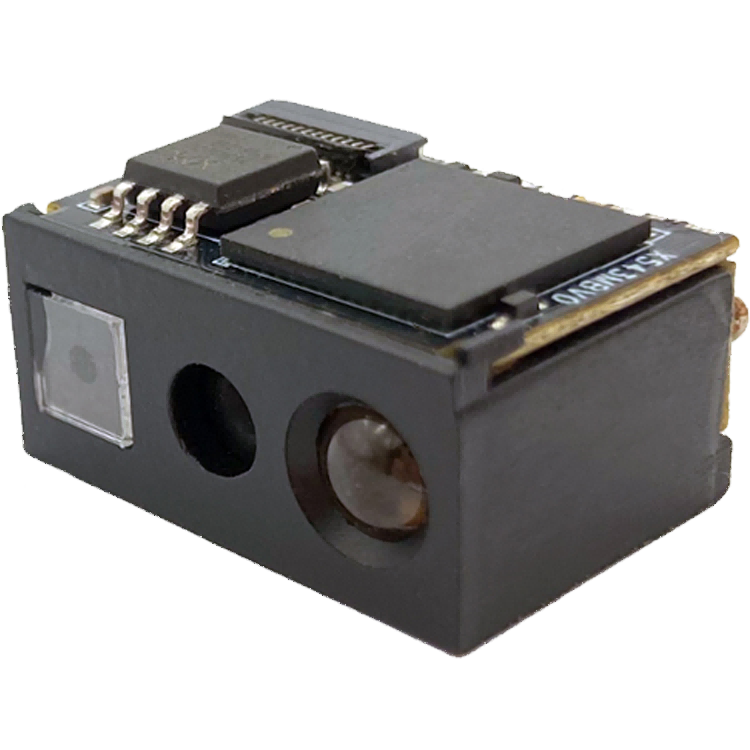

Our fixed-mount scanners boast cutting-edge technology, ensuring top-notch scanning performance. They excel at reading both 1D and 2D barcodes, including challenging codes like Direct Part Marking (DPM). Some of our high-end industrial fixed barcode scanners can capture barcode data with near-instantaneous precision. Equipped with built-in EtherNet/IP®, PROFINET, and PLC Link protocols, they facilitate seamless integration with PLC systems and more. With high-speed scanning capabilities and wide scanning areas, they maintain exceptional read rates even with minimal package gaps.

Connectivity and Integration:

Our fixed-mount scanners offer a range of connectivity options, including Ethernet, USB, RS233, RS485, serial communications, and Modbus interfaces. This flexibility enables seamless integration with programmable logic controllers (PLCs), warehouse management systems, and other industrial automation technologies. As a result, our fixed-mount scanners become the cornerstone of automated, data-driven workflows, elevating efficiency and accuracy to new heights.

In essence, fixed-mount barcode scanners represent the epitome of efficiency and accuracy in industrial and logistics settings. By enabling high-speed, hands-free barcode scanning on the move, they revolutionize workflows, enhance productivity, and minimize errors. As technology continues to advance, fixed-mount scanners will undoubtedly play a crucial role in shaping the future of industrial and logistics operations.

So, why choose our fixed barcode scanners?

Expertise and Technological Leadership: With over 20 years of experience in manufacturing and selling barcode scanning equipment, we are the technology leaders in this field. Our products undergo meticulous design and constant innovation to ensure they remain at the forefront of efficiency and performance.

Customization and Continuous Updates: We prioritize customer needs and feedback, continually updating and iterating our product line. This ensures a diverse product range that can perfectly meet your requirements.

Quality Assurance and Certification: Most of our products are CE, FCC, RoHS, and other certified, guaranteeing high quality and compliance. You can trust our products due to their strict quality control and certification processes.

Fast Delivery and Inventory Guarantee: With a vast inventory of products, you can quickly obtain the samples or bulk orders you need. Our fast delivery ensures you won't experience delays in your production schedule.

By choosing our fixed barcode scanners, you gain multiple advantages, including technological leadership, customization, quality assurance, and fast delivery, all of which contribute to greater efficiency and more reliable performance on your production line.

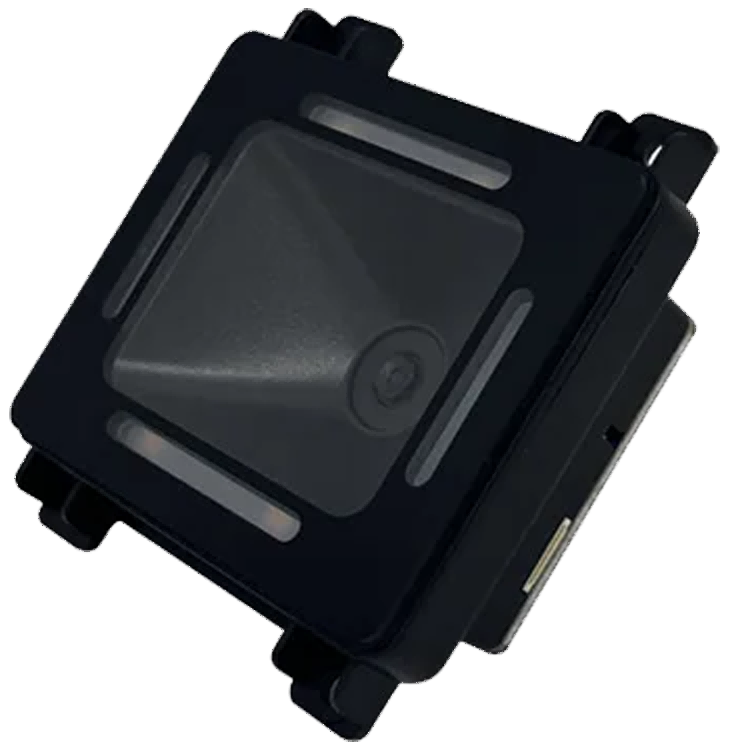

Meet Our A65 Fast Scanning Industrial Fixed Barcode Scanner!

1. Multiple Connectivity: Seamless connectivity via RS232, USB (HID; CDC) or Ethernet interfaces ensures compatibility with existing systems.

2. Simultaneous Scanning of Multiple Barcodes: Scan multiple barcodes at the same time to maximise productivity and minimise downtime.

3. Easily decode moving barcodes: Easily decode moving barcodes to keep production lines running smoothly.

4. Compact and easy to install: Due to its small size, it is very easy to install and integrates seamlessly into your workspace.

For more information, please contact us at sales@lonvill.com.

CONTACT US

CONTACT US

CONTACT US

are completed before submitting your inquiry.

We will respond within 24 hours.