SULOTIONS

Three-Color Light Source Scanner Enables Smart Manufacturing Traceability

Introduction:

In the era of Industry 4.0, barcodes have become the "digital gene" of product life. However, when faced with laser-etched microcodes, DPM (direct part mark) on reflective metal surfaces, or mechanical parts covered with oil, traditional scanning equipment is often helpless - the emergence of the H24 three-color smart scanner can solve the "blind scanning" problem in industrial scenarios.

Why does industrial scanning require disruptive innovation?

In the field of precision manufacturing, barcodes carry core data from raw material traceability to process control. However, the cruelty of the industrial environment is far beyond imagination:

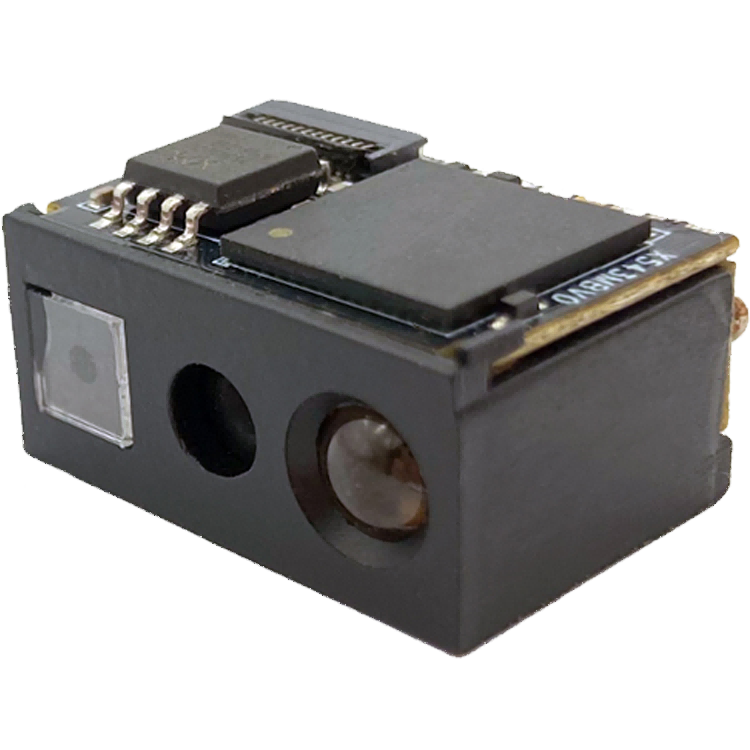

The three-color light source scanner was created to overcome these "unscannable codes". It is equipped with a third-generation decoding engine, which is like installing an industrial-grade AI brain on the scanner. It dynamically optimizes the decoding path through deep machine learning, and can accurately restore even a 50% incomplete DPM code.

Three-color light source system: optical revolution in industrial scanning

*Blue light: Capturing the micron-level bumps and grooves etched by laser, the laser code on the battery chip is nowhere to hide.

❷ Intelligent light field adaptation technology

*Identify inkjet codes of new energy batteries → Use "white light high-precision focusing" to prevent ink smudges

Practical decoding capabilities: defining a new benchmark for industrial scanning

| Challenge type | ||

| Stainless steel etching code | Success rate of traditional equipment | Three-color light source code reader solution |

| Tire sidewall curve code | ≤35% | Blue light 3D modeling + AI noise reduction(98%) |

| PCB Micro Dot Matrix Code | ≤40% | Red light waveguide tracking + curvature compensation(95%) |

| Injection molded parts hollow code | Unable to read | 100x optical magnification + macro decoding(99%) |

The "industrial endurance warrior" that produces 24 hours a day

"In the past, we had to change scanners twice per shift, but now a single device can handle three shifts throughout the day."

Covering the entire industry chain: from microelectronics to heavy machinery

Summary:

Why do many manufacturing companies choose three-color light source barcode readers? "It doesn't read barcodes, it reads the lifeline of manufacturing." When the tolerance of precision manufacturing approaches its limit, traditional scanning equipment has become a reef for yield control. The three-color spectrum reconstructs industrial visual logic and uses deep AI learning to break through the boundaries of physical decoding, ultimately achieving a 40% reduction in production line downtime, 99.99% traceability data integrity, and a 50% reduction in equipment comprehensive use costs.

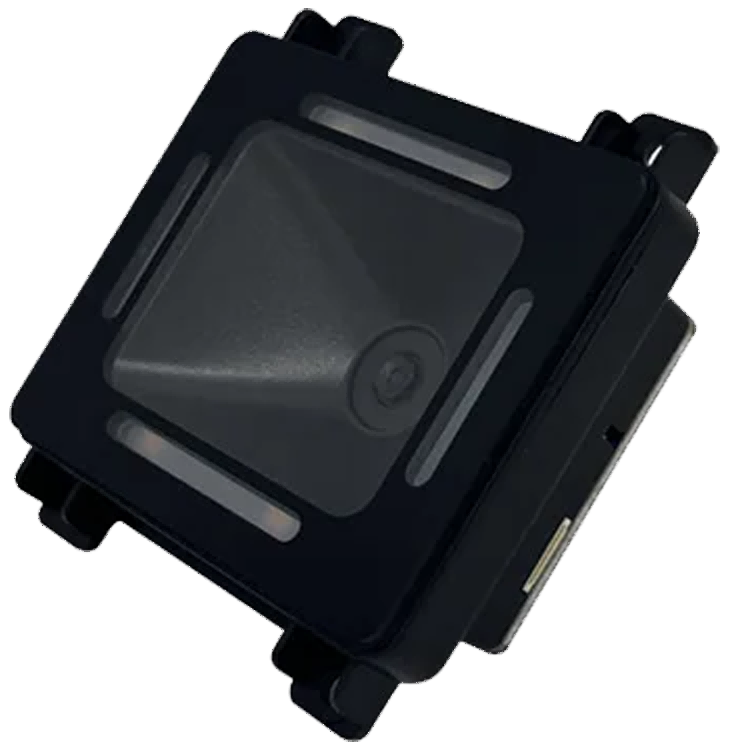

Our company's product H24 three-color light source barcode scanner meets most of the above requirements. If you need it, you can consult us. We can provide certificates and after-sales service.

CONTACT US

CONTACT US

CONTACT US

are completed before submitting your inquiry.

We will respond within 24 hours.