SULOTIONS

Comprehensive Guide to Choosing and Using Barcode Scanners for Quality Control

Barcode scanners are essential tools in quality control, ensuring the accuracy, traceability, and efficiency of manufacturing and production processes. Implementing a barcode scanner system can significantly enhance quality assurance processes by verifying product compliance with standards and tracking throughout the production cycle. Here is a comprehensive guide to selecting and using barcode scanners for quality control:

Choosing the Right Barcode Scanner

Types of Barcode Scanners:

1. Handheld Scanners: Suitable for flexible and convenient use in various environments.

2. Fixed Mount Scanners: Ideal for conveyor belt systems where items pass by the scanner.

3. Mobile Computers: These integrate scanning and computing capabilities, useful for inventory management and on-the-go quality checks.

Barcode Types:

Ensure the scanner supports the barcode types you use, such as 1D barcodes like UPC, EAN, or 2D barcodes like QR codes and DataMatrix.

Durability:

Choose scanners that can withstand environmental conditions of the quality control area, such as dust, moisture, and drops.

Connectivity:

Decide between wired and wireless options based on mobility needs.Ensure compatibility with existing software systems (USB, Bluetooth, Wi-Fi).

Scanning Range and Speed:

Consider the distance and speed at which barcodes need to be read. Some scanners are better for close-range scanning, while others are designed for long-range scanning.

Integrating Barcode Scanners into Quality Control

Software Integration:

Integrate scanners with quality control software to automate data entry, reduce errors, and enhance traceability. Use software that can handle the collected data and provide real-time analytics.

Database Management:

Maintain a comprehensive database of barcodes linked to product details, quality metrics, and inspection records.

Automation:

Install scanners in conveyor systems for automatic quality checks. Use triggers and sensors to automate the scanning process and minimize manual intervention.

Training and SOPs:

Train staff on the proper use of barcode scanners. Develop standard operating procedures (SOPs) for scanning processes to ensure consistency.

Error Handling:

Set up protocols for handling unreadable or incorrect barcodes. Ensure the system alerts operators of any issues to prompt immediate resolution.

Benefits of Using Barcode Scanners for Quality Control

Accuracy and Efficiency:

Reduces human error in data entry. Speeds up the inspection process.

Traceability:

Provides a clear audit trail of products and their quality status. Enhances accountability and transparency in the production process.

Real-time Data:

Offers real-time visibility into quality metrics. Helps in quick decision-making and corrective actions.

Cost Savings:

Reduces labor costs associated with manual inspections. Minimizes rework and waste by identifying defects early.

Popular Barcode Scanners for Quality Control

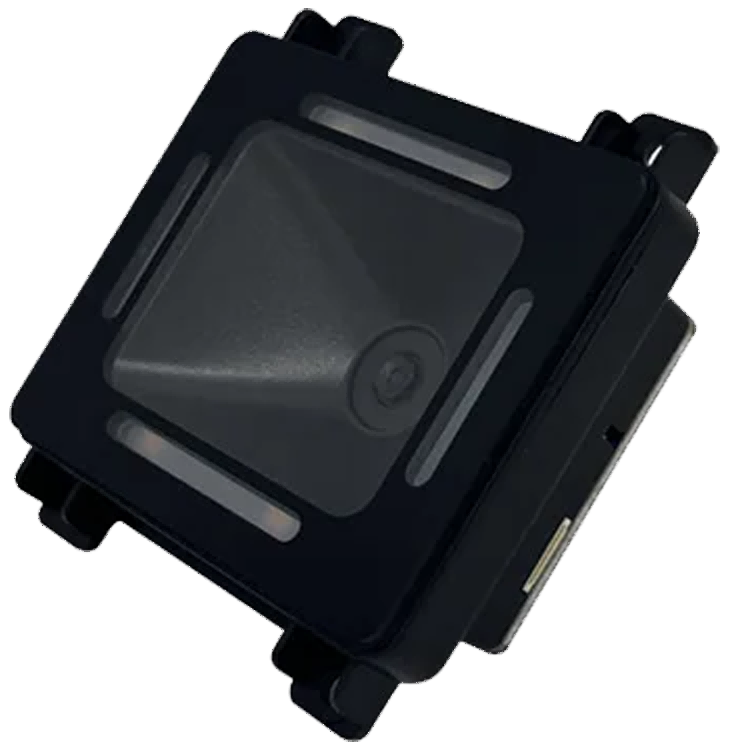

A65 Industrial Fixed Barcode Scanning

Rugged design for harsh environments.

Ideal for scanning direct part marks (DPM) and traditional bar codes.

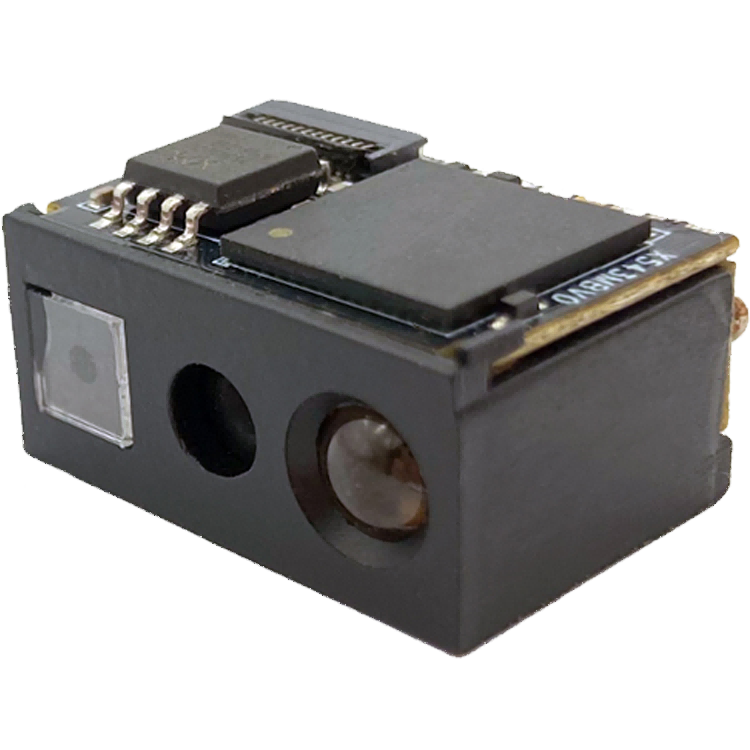

A6500 Intelligent Industrial Fixed DPM Scanning

Designed for industrial environments.

Long range scanning capability.

High performance reading of 1D and 2D barcodes.

Durable and reliable for use in harsh conditions.

Suitable for various environments, from factory floors to remote inspection sites.

Connects to wireless networks (Wi-Fi, Bluetooth, cellular) to access and update data in real-time.

Easily integrates with existing quality control software and databases for smooth data exchange.

Withstands harsh industrial conditions, including dust, moisture, and drops.

Combines scanning, computing, and communication functions in one device, simplifying workflows.

Implementation Tips

Pilot Testing:

Start with a pilot implementation to identify potential issues and refine the process before a full-scale rollout.

Continuous Improvement:

Regularly review and update your scanning processes and technologies to adapt to changing needs and advancements.

User Feedback:

Encourage feedback from operators to identify pain points and opportunities for improvement.

By choosing the right barcode scanner and effectively integrating it into your quality control system, you can achieve significant improvements in efficiency, accuracy, and overall product quality.

For more detailed IoT barcode scanning solutions, please contact us at: sales@lonvill.com

CONTACT US

CONTACT US

CONTACT US

are completed before submitting your inquiry.

We will respond within 24 hours.