Barcode Scanning Solutions for RVM

What's RVM

Reverse Vending Machines (RVM) are a special type of vending machine designed to accept, recycle, and process discarded items, typically plastic beverage containers such as plastic bottles, glass bottles, or aluminum cans. RVMs, such as automated recycling machines, automated return machines, envirobank recycling and redeem machines, allow users to deposit used or empty glass bottles, plastic bottles, or aluminum cans in exchange for rewards. The deposited recyclables are compressed, sorted, and analyzed based on the barcode on the bottles or cans, determining their weight, material, and brand. RVMs play a crucial role in promoting a circular economy system, environmental protection, energy conservation, and raise public awareness of environmental issues. These machines are usually placed in supermarkets, malls, or community areas for public convenience.In the context of countries implementing Producer Responsibility Schemes, the emergence of Reverse Vending Machine (RVM) type of equipments is a natural response.

The operational process of an RVM typically involves the following steps:

1. Item Deposit:Users place empty beverage containers into the machine.

2. Recognition and Classification:RVMs use sensors and identification technologies to recognize the type and material of the containers. This can include barcode scanning, visual recognition, and other technologies.

3. Value Assessment:The machine may assess the value of the container based on its type and material, usually in the form of a deposit or reward (instant rebate).

4. Storage or Processing:After receiving the container, the machine may store it in internal containers or process it into a more transportable form using built-in compressors or processing units.

5. Reward or Refund:Users can choose to receive corresponding rewards (such as discount coupons or points) or opt for a refund of the deposited item's deposit.

Why Does an RVM Machine Need a Barcode Scanner?

A Barcode scanner is crucial in an IoT connected RVM for the following reasons:

1. Item Identification:The barcode scanner identifies the barcode on the container. By scanning the barcode, the machine can accurately and quickly confirm the type and relevant information of the container.

2. Classification of Recyclables:The scanner helps the machine classify recyclables. It can recognize different types and materials of containers, such as plastic bottles, glass bottles, or aluminum cans.

3.Automation of Processing:By coordinating with the barcode scanner, the RVM machine can automate the processing of recyclables. The data feedback from the scanner triggers the machine's internal automated processing system, storing or compressing recyclables.

4. Value Assessment:Information embedded in the barcode, such as manufacturer and material, can be used by the RVM to assess the value of recyclables, determining the appropriate reward or deposit refund for users.

5. Tracking Recycling Data:The barcode scanner aids in tracking recycling data. The machine can record the type and quantity of each recycled item, providing administrators with data for monitoring and analysis of recycling effectiveness.

In summary, a Barcode scanner in an RVM provides the following benefits:

- Enhances the efficiency and accuracy of recycling, avoiding manual errors and delays.

- Reduces the cost and resource consumption of recycling by minimizing the need for labor and equipment.

- Strengthens the traceability and reliability of recycling, recording and analyzing data and statistics.

- Optimizes recycling services and experiences by offering various rewards and incentives.

How to Choose the Right Barcode Scanner for an RVM Machine:

Selecting a suitable Barcode scanner for an RVM involves considering various factors to ensure performance and reliability. Here are some recommendations:

1. Scanner Type:Depending on the installation location, space, and usage of the RVM, choose different scanner types, such as engine-only without a shell, a module with a shell, or a barcode scanner whole machine with IP67 protection level for waterproof and dustproof.

2. Compatibility:Based on the RVM's interface, protocol, and software, select a scanner with compatibility in terms of connection, communication method, drivers, encoding format, and data output.

3. Scanner Performance:Choose a scanner that meets the RVM's recycling speed, capacity, and accuracy requirements. Consider parameters such as scanning speed, scanning distance, scanning angle, scanning resolution, scanning depth, and scanning width. Generally, the scanning process takes place inside the RVM, so focus on the scanner's scanning angle, speed, and depth.

4. Durability:Considering the RVM's usage environment, frequency, and conditions, opt for a scanner with durability features such as waterproofing, dust resistance, shock resistance, and resistance to static electricity, working temperature, and working humidity.

5. Reading Different Types of Barcodes:Ensure the scanner can read common linear barcodes and 2D codes. Some applications may require special scanning capabilities, such as micro barcodes.

6. Ease of Maintenance:Choose a scanner that is easy to maintain and replace to ensure stable operation over an extended period.

7. Cost:While not the sole consideration, cost remains an important factor. Select a scanner that offers a good balance between cost and performance to meet budget requirements.

8. Brand and Reliability:Choose a reputable brand to ensure product reliability and after-sales service.

What Barcode Scanners do we have for RVM?

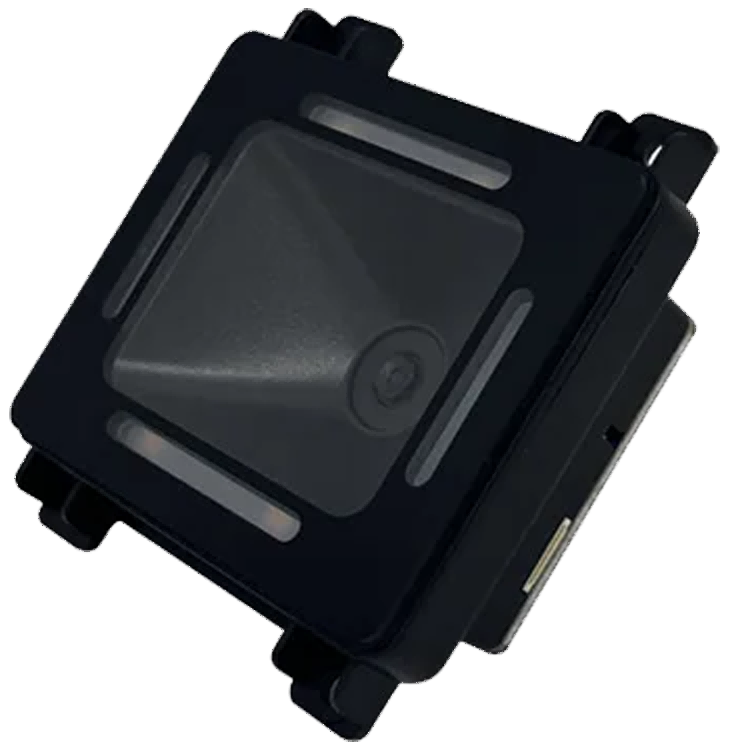

M0114 BARCODE SCANNER MODULE FEATURES

M0114 BARCODE SCANNER MODULE FEATURES

1. Fully Independent R&D and Patent Ownership:

Our product is the result of comprehensive independent research and development, backed by a complete patent system. It boasts a plug-and-play feature, eliminating the need for a cumbersome driver installation process.

2. Wide Voltage Design:

The design incorporates a wide voltage range, mitigating potential data transmission interruptions caused by voltage fluctuations. This enhances stability, ensuring the reliability of data uploads.

3. High-Performance Control Chip and Patented Software:

Utilizing a 32-bit control chip and proprietary software, our system smoothly decodes barcodes under various challenging conditions, including reflections, wrinkles, blurriness, and color variations. It can decode barcodes equally well in both strong and low light environments.

4. Full Tantalum Capacitor and Anti-Oxidation Optical Technology:

We address the issue of sensitivity decline over time in traditional scanners by employing full tantalum capacitors and anti-oxidation optical technology. This enhances the durability and stability of our product.

5. Multi-Interface Compatibility:

Our scanner seamlessly integrates with computers, POS terminals, and other smart devices. With multiple interfaces such as USB and RS-232, it offers flexible connectivity options.

6. High-Speed Recognition and Powerful Image Algorithms:

Featuring a high-speed industrial CMOS sensor and a custom lens, our system efficiently recognizes barcodes on freely falling items. The proprietary image algorithms from years of iterative optimization ensure smooth barcode recognition under various complex conditions.

7. Low Power Consumption Design:

Careful selection of the main chip, low-power optimization, and dedicated sensors and lighting contribute to high performance while maintaining ultra-low power consumption. This resolves issues related to glaring lights and ensures reliable data transmission under various power supply scenarios.

8. Large Window, Deep Depth of Field, Broad Coverage:

The design incorporates a large window and deep depth of field, ensuring the ability to scan a wider area under different circumstances. It provides extensive scanning coverage, making it suitable for various applications, such as in the circular economy system, in-counter barcode scanners, etc.

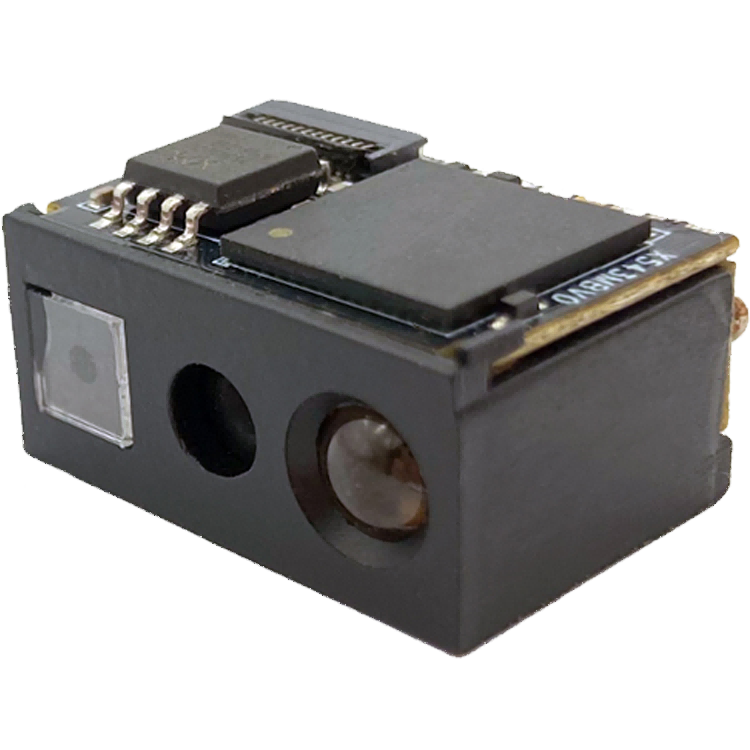

M0112 BARCODE SCANNER ENGINE FEATURES

M0112 BARCODE SCANNER ENGINE FEATURES

1. High-performance megapixel 1280*800 CMOS sensor

2. Crosshair laser line sight for precise aiming

3. Optional OCR reading function

4. Applications PDA/Mobile Terminal/Tablet/Kiosk/Self-serve RVM Kiosk etc.

For more information, you can fill out the form below or contact us directly by email: sales@lonvill.com

CONTACT US

CONTACT US

CONTACT US

are completed before submitting your inquiry.

We will respond within 24 hours.