SULOTIONS

How to Enhance Your Industrial Automation with Machine Vision Cameras?

What is a Machine Vision Camera?

A machine vision camera is a specialized type of camera designed for industrial and automation applications. Unlike regular consumer-grade cameras, machine vision cameras are purpose-built for industrial use cases. They incorporate advanced features such as high-speed image acquisition, low latency, precise synchronization, and specialized optics to perform optimally in demanding environments. Machine vision cameras are used to capture accurate visual data, process and analyze images using sophisticated algorithms and software, and seamlessly integrate into automation systems. They are crucial for advanced computer vision applications in industries such as manufacturing and logistics.

Components of Machine Vision Cameras:

Sensor: Machine vision cameras use specialized sensors, such as charge-coupled devices (CCD) or complementary metal-oxide-semiconductor (CMOS) sensors, to convert light into electrical signals that can be processed by a computer.

Optics: Machine vision cameras often incorporate lenses or filters to focus light and improve image quality. Some cameras may also include infrared or ultraviolet filters for capturing images in specific wavelength ranges.

Interface: Machine vision cameras typically feature a digital interface, such as Gigabit Ethernet or USB, enabling communication with a computer or other device. This interface facilitates the transfer of image data for processing and analysis.

Processing and Analysis Software: Machine vision cameras are often accompanied by software facilitating image processing and analysis. This software enables tasks like object detection, feature extraction, dimensional measurement, defect identification, and pattern recognition.

These components work together to capture high-quality visual data and process it for various industrial applications.

How Machine Vision Cameras Work:

Machine vision cameras capture high-quality visual data and integrate with automation systems to enable advanced computer vision applications in industrial environments. Here's an overview of how they work:

Image Capture: Equipped with specialized sensors and optics, machine vision cameras capture high-resolution, detailed images of target objects or scenes. They operate at high frame rates and resolutions to enable real-time or high-speed image acquisition.

Image Processing: Captured images undergo processing using advanced algorithms and software, involving tasks like object detection, feature extraction, dimensional measurement, defect identification, and pattern recognition. The aim is to extract relevant visual information.

Automation and Integration: Designed to seamlessly integrate with automation systems, machine vision cameras offer features like triggering capabilities, precise exposure control, and robust software integration. This enables smooth integration into industrial environments.

By combining image capture, processing, and automation integration, machine vision cameras enable a wide range of applications in manufacturing, logistics, and other industries, including quality control, inspection, object recognition, and measurement.

Types of Machine Vision Cameras:

There are several types of machine vision cameras, each with unique strengths and weaknesses:

Area Scan Cameras: Capture rectangular images of scenes, suitable for relatively stationary objects in various resolutions and sizes.

Line Scan Cameras: Capture a single line of pixels at a time, ideal for moving objects on conveyor belts or production lines, specializing in high-speed image capture.

Thermal Cameras: Capture images based on object temperatures, used for monitoring temperature, detecting hot spots, or identifying objects in low-light environments.

These examples illustrate the variety of machine vision cameras available, with the choice depending on specific application requirements such as resolution, speed, lighting conditions, and integration with other systems.

Application Scenarios:

Quality Control and Inspection: Machine vision cameras are extensively used in manufacturing industries for quality control and inspection tasks. They can detect defects, irregularities, or deviations in products with high accuracy and speed. Examples include inspecting surface flaws in manufactured goods, identifying misaligned components, or checking for proper labeling and packaging.

Object Recognition and Tracking: Machine vision cameras excel in identifying and tracking objects in various environments. In logistics, they can track packages along conveyor belts, sort items based on predefined criteria, and optimize warehouse operations. In robotics, they enable robots to recognize and manipulate objects accurately in dynamic environments.

Measurement and Dimensional Analysis: Machine vision cameras are employed for precise measurement and dimensional analysis in industries such as automotive, aerospace, and electronics manufacturing. They can accurately measure distances, angles, and dimensions of components, ensuring compliance with specifications and standards.

Pattern Recognition and Authentication: Machine vision cameras are utilized for pattern recognition and authentication tasks in security, retail, and banking sectors. They can recognize patterns such as fingerprints, barcodes, QR codes, and facial features, enabling authentication processes, access control, and fraud detection.

Guidance and Navigation: Machine vision cameras play a crucial role in autonomous vehicles, drones, and robotic systems for guidance and navigation purposes. They provide real-time visual feedback to navigate through environments, avoid obstacles, and perform complex tasks autonomously.

Advantages of Machine Vision Cameras:

High Accuracy and Precision: Machine vision cameras offer exceptional accuracy and precision in capturing and analyzing visual data, ensuring reliable results in industrial applications.

High Speed and Throughput: Machine vision cameras operate at high frame rates and resolutions, enabling real-time or high-speed image acquisition and processing, thus enhancing productivity and efficiency in industrial processes.

Non-destructive Testing: Machine vision cameras facilitate non-destructive testing of products and materials, eliminating the need for manual inspection methods that may damage or alter the integrity of the objects being inspected.

Consistency and Reliability: Machine vision cameras provide consistent and reliable results, unaffected by factors such as fatigue, human error, or environmental conditions, ensuring uniformity in inspection and measurement tasks.

Cost-effectiveness: While initial setup costs may be significant, machine vision systems offer long-term cost savings by reducing labor costs, minimizing errors, and improving productivity and product quality.

Versatility and Flexibility: Machine vision cameras are versatile and adaptable to a wide range of applications and environments. They can be easily integrated into existing automation systems and reconfigured for different tasks, offering flexibility in manufacturing processes.

Data-driven Decision Making: Machine vision systems generate valuable data and insights that can be utilized for process optimization, predictive maintenance, and decision-making, contributing to overall business efficiency and competitiveness.

In summary, machine vision cameras play a vital role in various industries by enabling automation, improving quality control, enhancing productivity, and driving innovation through advanced visual inspection and analysis capabilities.

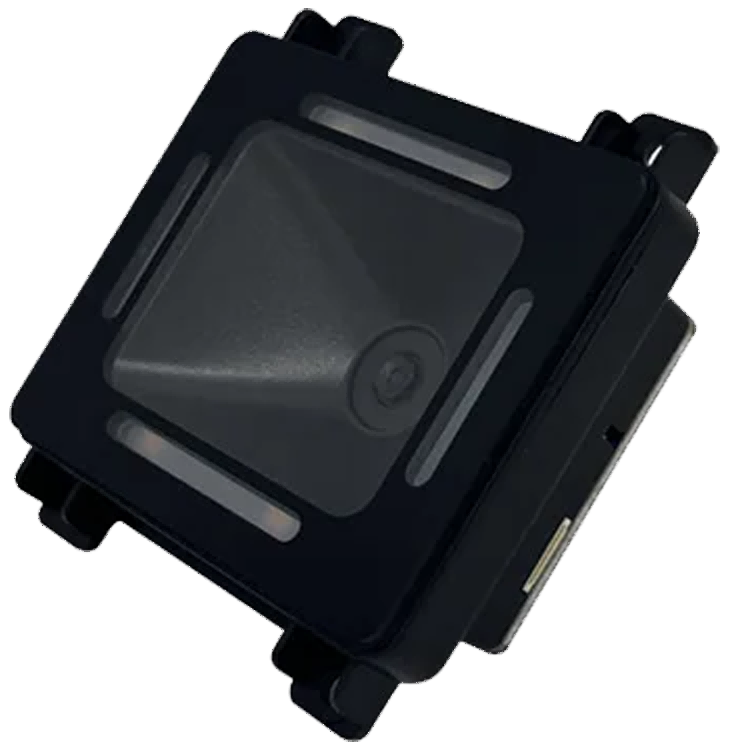

Enhance Your Industrial Automation with Our Cutting-Edge A6500 Machine Vision Camera!

Advantages of A6500 Machine Vision Barcode Scanner:

Unlock Efficiency and Precision in Barcode Scanning with Our State-of-the-Art Solution!

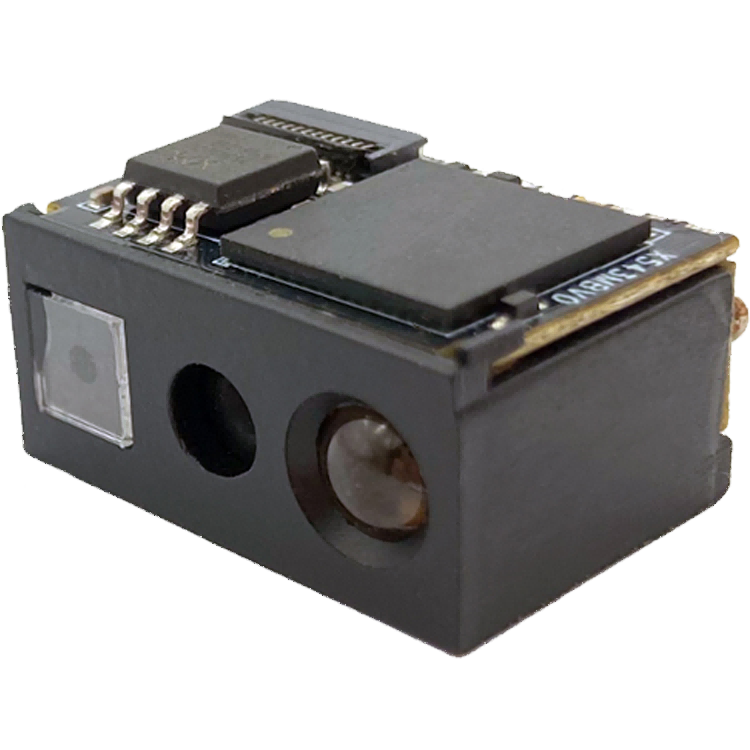

Our machine vision barcode scanning system is powered by advanced sensors and deep learning algorithms, ensuring exceptional image quality and robust decoding of various barcode formats. You can rely on our solution to efficiently and accurately read barcodes, even in challenging industrial environments.

But that's not all. Our system features a rich array of IO interfaces, enabling seamless integration with multiple input and output signals. With convenient features like the top-mounted ring indicator light and waterproof debugging button, you can easily observe and troubleshoot operations for swift deployment and optimization.

With dual-sided waistline status indicator lights providing real-time, multi-angle visibility, monitoring your system's performance has never been easier. Plus, support for a range of transmission protocols including TCP, Serial, FTP, and Profinet ensures compatibility with your existing setup.

Worried about harsh industrial conditions? Our IP67-rated protection means our system fearlessly withstands even the toughest environments, ensuring reliability and longevity.

Choose from a variety of lens options to suit your specific application needs (06mm-16mm), covering industries such as 3C, food and pharmaceuticals, electronics and semiconductors, automotive components, and industrial automation, logistics, and warehousing.

With communication protocols including SmartSDK, TCP Client, Serial, FTP, TCP Server, Profinet, MELSEC, Ethernet/IP, ModBus, Fins, and SLMP, seamless integration into your existing workflow is guaranteed.

Don't settle for subpar barcode scanning solutions. Elevate your operations with our machine vision barcode scanning system and experience unparalleled efficiency, accuracy, and reliability. Contact us today to learn more!

CONTACT US

CONTACT US

CONTACT US

are completed before submitting your inquiry.

We will respond within 24 hours.