Production Inspection

Elevating Manufacturing Quality: The Role of Machine Vision Technology

In the realm of modern manufacturing, production inspection stands as a critical step to ensure products meet specifications and standards. However, traditional inspection methods face numerous challenges, including defect identification, maintaining consistency across production lines, managing vast amounts of data, and ensuring effective communication between inspection teams and production units. To address these issues, advanced technologies such as machine vision have emerged as a transformative solution.

Challenges in Production Inspection:

Production inspection, a pivotal aspect of the manufacturing process, encounters a range of complex issues. Challenges include the identification of defects or non-compliant products, maintaining consistency across various production lines, managing substantial amounts of data, and ensuring effective communication between inspection teams and production units.

Application of Machine Vision:

Machine vision technology, leveraging intelligent image recognition and analysis, offers innovative solutions to enhance production inspection. Aimed at improving product quality and reducing the number of non-compliant items, machine vision plays a crucial role in the following aspects:

Automated Quality Inspection: Machine vision systems efficiently and accurately detect surface defects, dimensional variations, and more, achieving automated quality inspection and reducing reliance on manual inspection.

High-Precision Dimensional Measurement: Machine vision systems can precisely measure product dimensions, ensuring alignment with design specifications—an especially vital function in industries with stringent dimensional control requirements.

Defect Classification and Analysis: Machine vision systems categorize and analyze detected defects, providing manufacturers with valuable insights into potential issues within the production process.

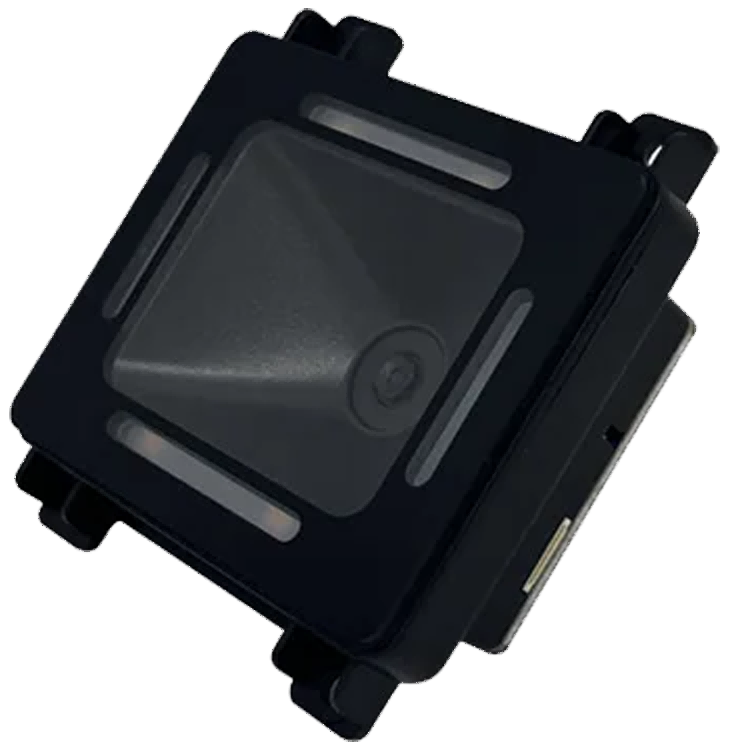

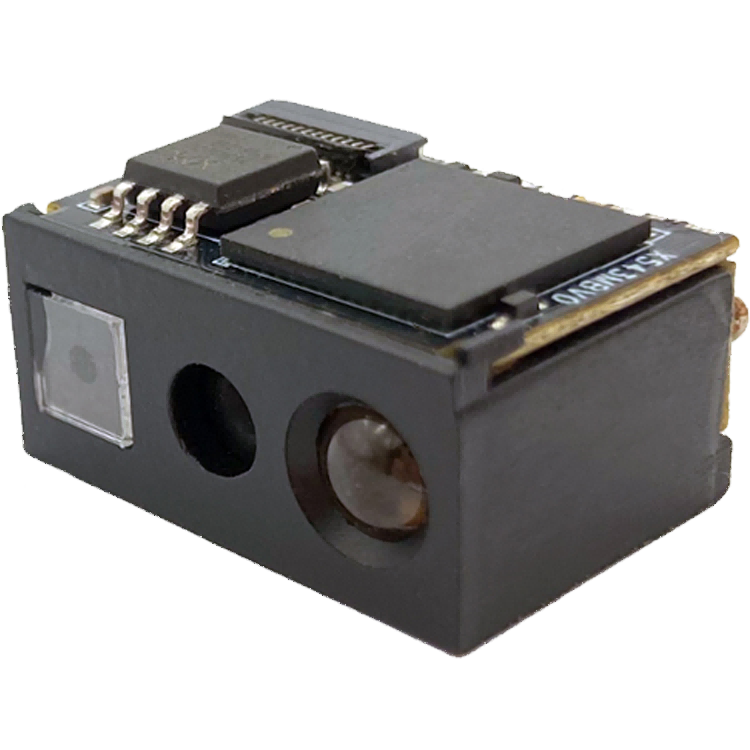

Recommended Machine Vision Product:

Among the myriad of machine vision products available, LONVILL machine vision products stand out for their advanced technology and flexibility. By combining LONVILL's barcode scanning and machine vision technologies, businesses can achieve comprehensive and intelligent production inspection. This combination not only provides product identification but also offers highly detailed detection for product quality, realizing more efficient and accurate quality control.

Equipped with real-time monitoring systems, LONVILL products can issue alerts promptly upon detecting anomalies, aiding businesses in swift issue resolution and minimizing the entry of non-compliant products into the market. Through data analysis and continuous improvement, LONVILL machine vision systems support manufacturing industries in their pursuit of ongoing enhancements in production quality.

CONTACT US

CONTACT US

CONTACT US

are completed before submitting your inquiry.

We will respond within 24 hours.