SULOTIONS

How to speed up the packaging inspection process for product production

Application of Barcode Scanning in the Packaging Industry:

Product Identification and Traceability:

Each barcode on packaging boxes or products contains unique information such as batch numbers, production dates, and product types. By scanning these barcodes, manufacturers can trace the production process, making it easier to identify and address potential quality issues.

Order Processing and Inventory Management:

Barcode scanning is used for quick and accurate order processing and inventory management. Barcodes on each packaging box can rapidly match with order information, ensuring the correct products are packaged and reducing human errors. Real-time updates of inventory information help in better supply chain management.

Quality Control:

Barcode scanning is employed in packaging for quality control. By scanning barcodes on products, the system can verify the accuracy, completeness, and consistency of the products. In case of abnormalities, the system immediately issues alerts for timely corrective measures to ensure only qualified products enter the market.

Enhancement of Production Line Efficiency:

Barcode scanning is utilized to track the movement and flow of products on the production line, assisting in managing the overall efficiency of the production line. Real-time monitoring of each scanning point allows businesses to better understand bottlenecks and improvement areas, optimizing the production process.

Custom Packaging Services:

In industries requiring customized packaging, barcode scanning is used to identify and track the requirements for custom packaging. Scanning systems can automatically adjust the production line based on different packaging specifications requested by customers, ensuring each product meets customized requirements.

Real-time Data Analysis:

Data collected by barcode scanning systems can be used for real-time data analysis, helping businesses identify bottlenecks on the production line, optimize packaging processes, improve production efficiency, and make more strategic decisions.

Significance of Barcodes in Packaging:

UPC (Universal Product Code):

Used for inventory tracking, POS transactions, and product identification.

EAN (European Article Number):

Widely used in Europe for product identification, retail scanning, and inventory management.

QR Code (Quick Response Code):

Used for tracking and tracing, product registration, warranty processes, marketing activities, promotions, sustainability, recycling, and strengthening supply chain management.

DataMatrix:

Aids in tracking, identifying, and managing products, especially in pharmaceuticals, electronics, and asset tracking.

Code 39:

Used for product identification, inventory control, and logistics, encoding alphanumeric data.

Code 128:

Utilized for inventory control, product information, and improving supply chain efficiency, especially in transportation labels.

GS1-128:

Adopted in supply chain and logistics applications for storing data such as batch numbers, expiration dates, and serial numbers.

Interleaved 2 of 5 (ITF-14):

Used in packaging and transportation of cartons, encoding data like product codes and quantities for accurate inventory control and warehouse operations.

Choosing the Right Barcode Scanning Technology:

i. Factors to Consider when Choosing Barcode Scanning Solutions:

Scanning Speed:

In high-volume packaging environments, selecting a high-speed, accurate barcode scanner can maximize productivity and efficiency.

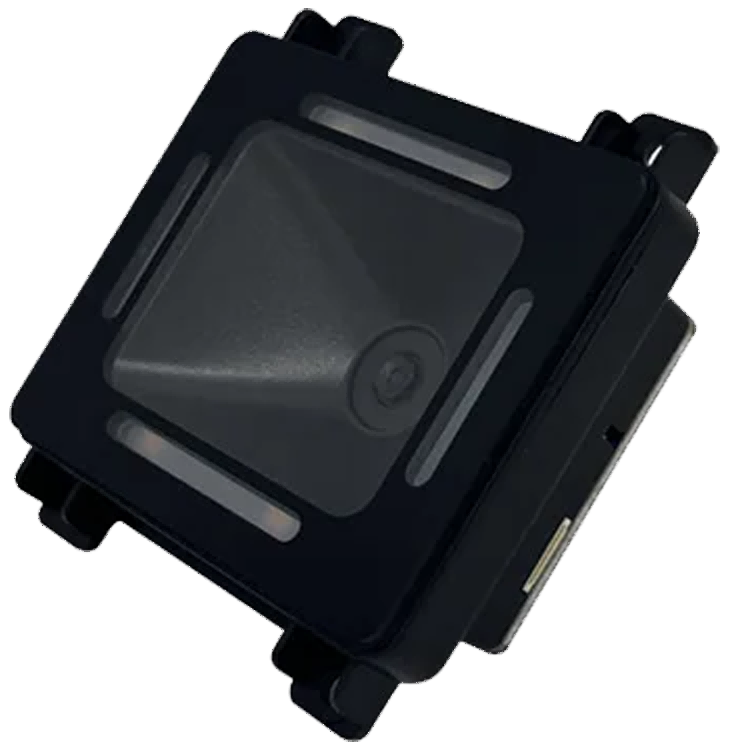

A65 high speed fixed barcode scanner

Compatibility:

Ensure that the scanning solution is compatible with the barcode symbols used in packaging operations and can integrate seamlessly with current software and hardware.

Connectivity and Integration:

Check the connectivity features of the scanning device, ensuring it can connect to your preferred devices and integrate effectively with your infrastructure, such as inventory management software or warehouse management systems.

Cost:

Consider the overall cost of the barcode scanning solution, including purchasing or leasing, maintenance, and software or license pricing. Find the best price-to-feature ratio.

ii. Recommended Barcode Scanning Technology for Packaging Applications:

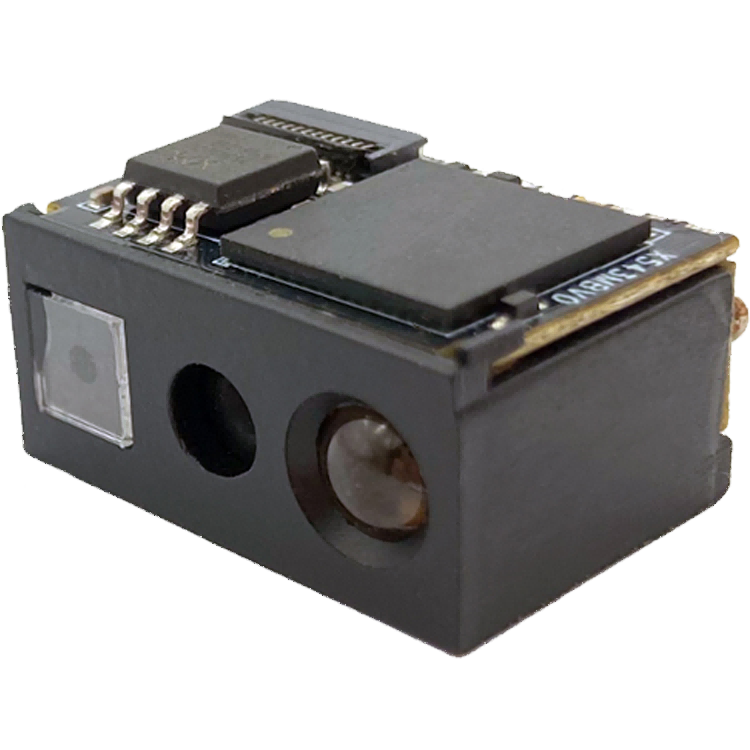

It is recommended to adopt camera-based barcode scanning technology, such as the image-based LONVILL RK31A Data Collector.This PDA has a variety of professional barcode engines to choose from (Honeywell HS7, Zebra se4710, NLS-CM60, NLS-N1), which can meet your various barcode scanning requirements.

If you have any questions about barcode scanning or item packaging detection and tracking, feel free to consult LONVILL staff. They will provide detailed explanations and tailor solutions based on your needs, ensuring your success in the packaging industry.

CONTACT US

CONTACT US

CONTACT US

are completed before submitting your inquiry.

We will respond within 24 hours.