Introduction to DPM Codes

Characteristics of DPM Codes

Data Matrix Codes, often referred to as DPM (Direct Part Marking) codes, are a type of 2D barcode that consists of black and white cells

arranged in a square or rectangular pattern. These codes are designed to hold a significant amount of data in a compact space, offering

several advantages over traditional 1D barcodes:

1.High Data Density: DPM codes can store a large volume of information within a small area, making them ideal for applications where

space is limited.

2.Error Correction: With built-in error correction algorithms, DPM codes can still be accurately read even if part of the code is damaged

or obscured.

3.Durability: Since DPM codes are directly marked on the surface of an item, they are more resistant to wear and tear compared to labels

or stickers.

Requirements and Features of DPM Code Readers

To accurately read and decode DPM codes, specialized DPM code readers are required. These devices must meet certain requirements and

possess specific features to handle the unique challenges posed by DPM codes:

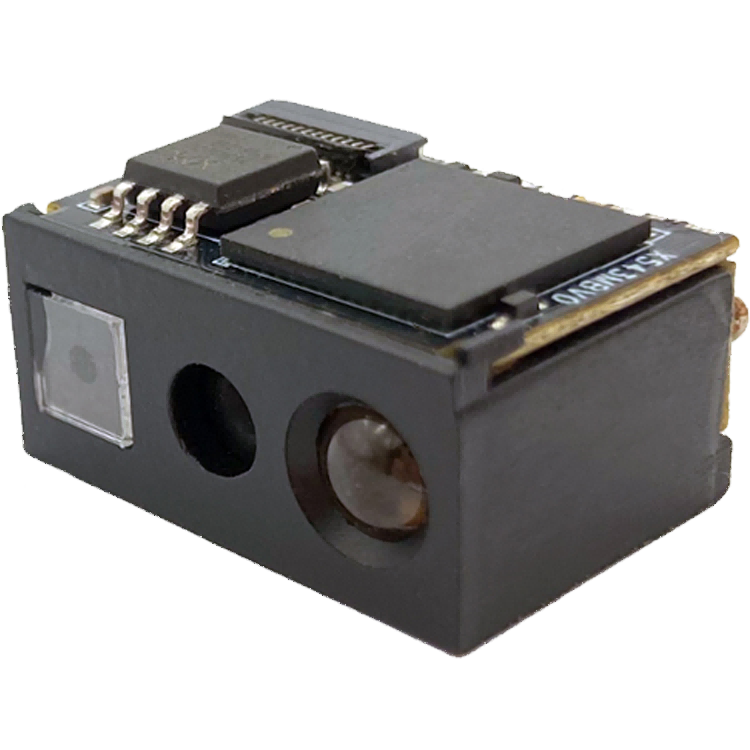

1.High-Resolution Cameras:

Essential for capturing the details of DPM codes, especially on small or curved metal surfaces.Capable of handling various contrasts and

reflective surfaces.

2.Advanced Lighting Systems:

Multi-angle and multi-source lighting systems help to illuminate DPM codes on different materials and surfaces, reducing issues caused

by reflections and shadows. Incorporation of infrared, ultraviolet, and multi-colored lighting can enhance the visibility of DPM codes on

challenging surfaces.

3.Sophisticated Image Processing Algorithms:

Enhanced algorithms are necessary to improve image quality, reduce noise, and increase the readability of low-contrast and partially

damaged codes. Automatic adjustments for focus, exposure, and gain to adapt to varying environmental conditions.

4.Robustness and Durability:

DPM code readers are often used in industrial settings and must be rugged enough to withstand harsh conditions, including dust, moisture,

and impact. Common protection ratings, such as IP65 or higher, ensure reliable performance in demanding environments.

5.Real-Time Processing Capabilities:

It is crucial to quickly and efficiently decode DPM codes on high-speed production lines.

6.Versatile Communication Interfaces:

Supports various communication protocols such as USB, RS232, and Ethernet to connect with different systems and devices.

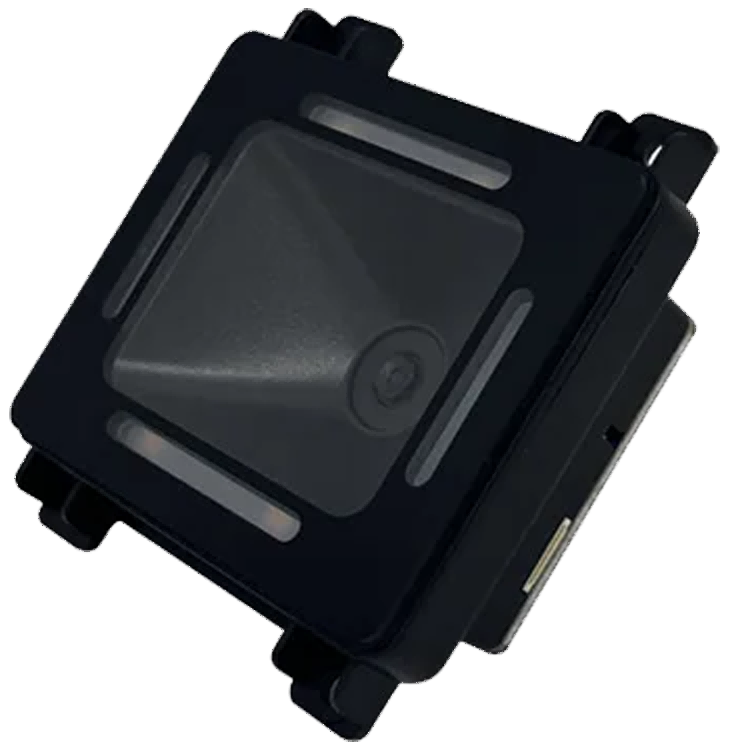

LONVILL's A65P model is optimized for recognizing DPM codes, making it highly preferred in applications requiring DPM code recognition.

CONTACT US

PRODUCT RECOMMENDATIONS

CONTACT US

CONTACT US

are completed before submitting your inquiry.

We will respond within 24 hours.