Direct Part Marking (DPM) Code Reading

Decoding DPM Barcodes: A65 Fixed Scanner and IDH3013 Handheld Solution

Introduction:

Direct Part Marking (DPM) has emerged as a crucial method for industries like aerospace, automotive, and electronics manufacturing to ensure permanent and durable tracking of manufactured parts. However, decoding DPM barcodes poses unique challenges due to factors such as low contrast, varied surfaces, and complex scanning environments.

Challenges in DPM Barcode Scanning:

Scanning DPM barcodes becomes intricate when faced with low contrast, diverse surfaces, and complex backgrounds. Traditional black markings on white backgrounds often fall short, especially with curved or uneven surfaces and highly reflective materials. Efficient barcode reading becomes a necessity to maintain seamless operations on industrial production lines.

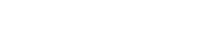

A65 Fixed Scanner – A Comprehensive Solution:

The A65 Fixed Scanner is equipped with features designed to tackle the challenges posed by decoding DPM barcodes.

Intelligent Lighting System:

The built-in intelligent light source calibration accommodates various materials, shapes, and complex backgrounds. It caters to reflective surfaces, metal codes, curved surfaces, ensuring diverse scanning requirements are met with precision.

Flexible I/O Expansion Interface:

The A65 supports external trigger scanning through I/O expansion interfaces, facilitating easy integration and control of external devices. With 1 channel of opto-isolated input and 2 channels of opto-isolated output, the scanner enhances scanning efficiency, offering seamless integration into industrial processes.

IP65 Protection Rating:

The IP65 protection rating ensures the scanner's durability in challenging industrial environments by preventing foreign object intrusion and protecting against splashes in various directions.

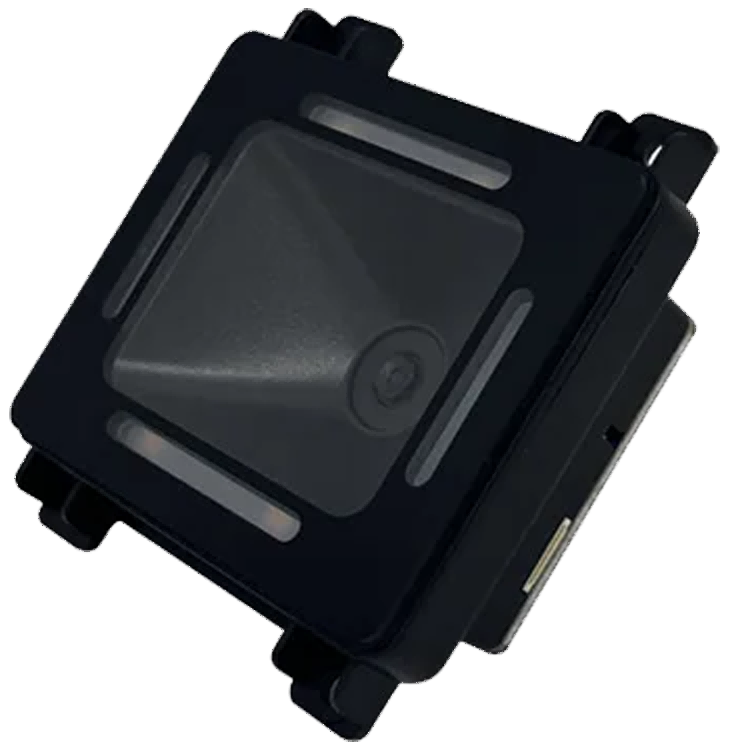

IDH3013 Handheld Scanner – Unleashing Decoding Capabilities:

The IDH3013 Handheld Scanner is tailored to address the unique requirements of decoding DPM barcodes in various industries.

Advanced Code Reading Algorithm:

The handheld code reader adopts a sophisticated code reading algorithm, providing excellent decoding capability for DPM. It excels in reading different types of one-dimensional and two-dimensional codes, even in challenging conditions such as spots, defects, and low contrast ratios.

Robustness and Efficiency:

The scanner offers robust performance, reading codes continuously and in batches, enhancing code reading efficiency. It is adaptable to industries like PCB, new energy, consumer electronics, semiconductor, and automobile parts.

Versatile Communication Protocols:

Supporting multiple communication protocols, including TCP Client, Serial, FTP, Profinet, the IDH3013 ensures seamless integration into diverse industrial setups.

Illumination System:

Adopting an illumination system that provides direct lighting and diffused reflection lighting, the scanner ensures optimal visibility and decoding accuracy.

Conclusion:

In the realm of DPM barcode decoding, the A65 Fixed Scanner and IDH3013 Handheld Scanner stand as robust solutions. They address the challenges posed by low contrast, varied surfaces, and complex environments, offering a comprehensive and reliable decoding experience. By investing in these advanced scanning technologies, industries can streamline their operations, enhance tracking capabilities, and ensure the efficiency and durability of their production processes.

For more information about our fixed barcode scanner solutions, please contact us.

Email: sales@lonvill.com

CONTACT US

CONTACT US

CONTACT US

are completed before submitting your inquiry.

We will respond within 24 hours.